Machine Operations

Automatic Tool Changer

Block Surfacing

Blue Print Boring

Boring & Sleeving

Circular Interpolation

Connecting Rod Boring

Cylinder Boring

Cylinder Head Resurfacing

Lifter Boring

Line Boring

Multi Purpose CNC (Custom Parts)

Thrust Cutting

Overview

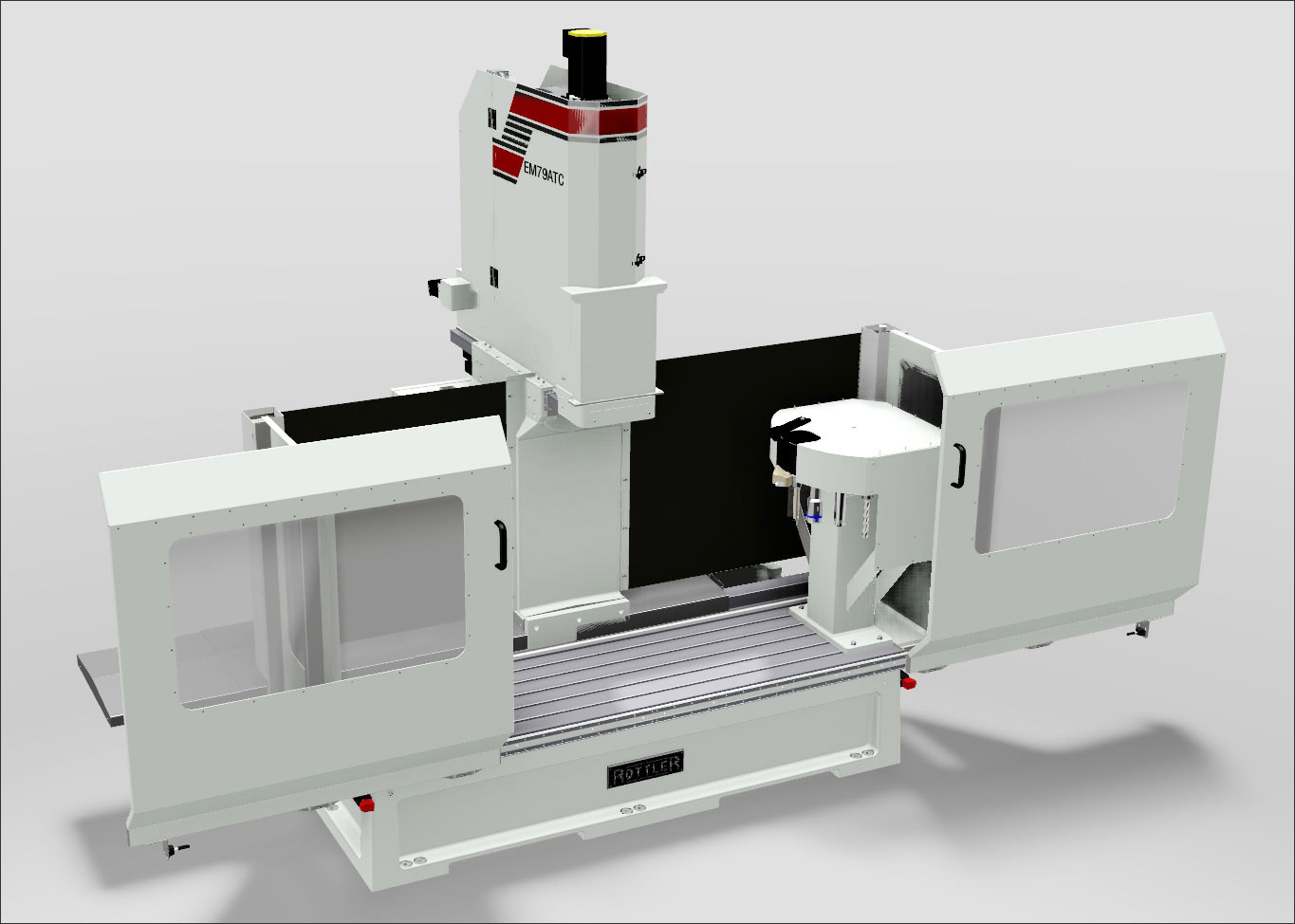

The Rottler EM70 Series are designed for the small - medium size diesel engine rebuilder as well as the performance engine builder. The EM79ATC features an Automatic Tool Changer.

Rottler’s totally new, next generation CNC control found in the EM Series machines continues to give users unmatched speed of learning and ease of use when probing/digitizing without the need of additional cumbersome and expensive software. This advanced 4C software lets users know they are machining with the most state-of-the-science equipment available. Read more in the "Control" tab below.

Features

For more information: See brochure or contact us at +1 (253) 872-7050

Standard Equipment

Control

Rottler Exclusive Touch Screen Programming

The conveniently located control pendent centralizes the machine controls. Only the buttons and interactive menus required for a particular machine operation are displayed. Machine operations can easily be done manually or automatically, with the ability to store programs in memory. Digital readout allows the operator to accurately monitor position at all times. Control operates in metric and inch systems.

Fully Programmable Cycles

Conversational 3 axis CNC control, PC based with Windows Operating System.

Dimensions and Control through Touch Screen:

- Program Bore Centers, Exact Depth, Speed, Feed, etc.

- Machines complete bank or main line in Automatic Cycle.

- Lower Offset Boring allows lower sleeve repair in Automatic Cycle.

- Circular Interpolate Counterbores for Radius Undercut or Wide Counterbores.

- Surfacing/Milling – Multiple Pass – program for Rough Cut and Finish Cut for superior surface finish.

- Line Boring – program the bearing bores and length of each bore and the machine automatically moves from bore to bore, completing the line unattended.

- Face Main Line Thrust Faces square to centerline of Crankshaft using Rottler Circular Interpolation software.

Specifications

| EM79ATC Machine Specifications | American | Metric |

|---|---|---|

| Control | Automatic | |

| Touch Screen | 15" | 381mm |

| Machine Height | 118" | 2989mm |

| Table - Size | 91.6" x 22.6" | 2325 x 575mm |

| Table - T Slots | 5 | |

| Travel - Horizontal (X Axis) | 72" | 1829mm |

| Travel - In/Out (Y Axis) | 14" | 355mm |

| Travel - Vertical (Z Axis) | 18" | 457mm |

| Travel - Spindle Nose to Table | 40.44" | 1027mm |

| Travel - Spindle Center to Column | 21.7" | 551mm |

| Spindle - Taper | CAT 40 | CAT 45 |

| Spindle - Diameter | 3.8" | 96.5mm |

| Spindle - Rotation Speed | 0 to 2000 RPM | |

| Spindle - Motor | 6 HP | 4.5 Kw |

| Tool Changer | Optional | |

| Cylinder Bore Range (with Optional Cutterheads) | .75" - 7" | 19 - 178mm |

| Line Bore Range (with Optional Cutterheads) | 1.9" - 5.9" | 48.5 - 150mm |

| Surfacing Cutterhead Diameters | 10", 14", X" & X" | 250, 360, X & Xmm |

| Dimensions - Machine | 69D x 153W x 118" H | 1745D x 3877W x 2989mm H |

| Dimensions - Floor Space Requirements | 94D x 153W" | 2388D x 3877Wmm |

| Dimensions - Shipping | 88D x 117W x 90" H | 2235D x 2972W x 2286mm H |

| Machine Weight | 10000 lbs | 4845 kg |

| Electrical Requirements | 208-240V, 30A, 50/60Hz, 3/1Ph | |

| Air Requirements | 1 cfm @ 90 psi | 28 l/min @ 6 bar |

| Paint Color Code | RAL9002 (Grey White) | |